Temperature stability is a critical factor in the performance of laboratory calibration weights, and it can significantly impact the accuracy and reliability of weight measurements. Here's how temperature stability affects laboratory calibration weights:

Coefficient of Thermal Expansion (CTE):

Materials used in the construction of calibration weights have a coefficient of thermal expansion (CTE), indicating how much the material expands or contracts with changes in temperature. Temperature stability ensures that the CTE is known and consistent, minimizing the impact of temperature variations on the weight's mass.

Dimensional Changes:

Temperature changes can lead to dimensional changes in materials. For calibration weights to maintain accuracy, the materials used must have stable dimensions across a range of temperatures. This stability is critical for achieving precise and reliable measurements.

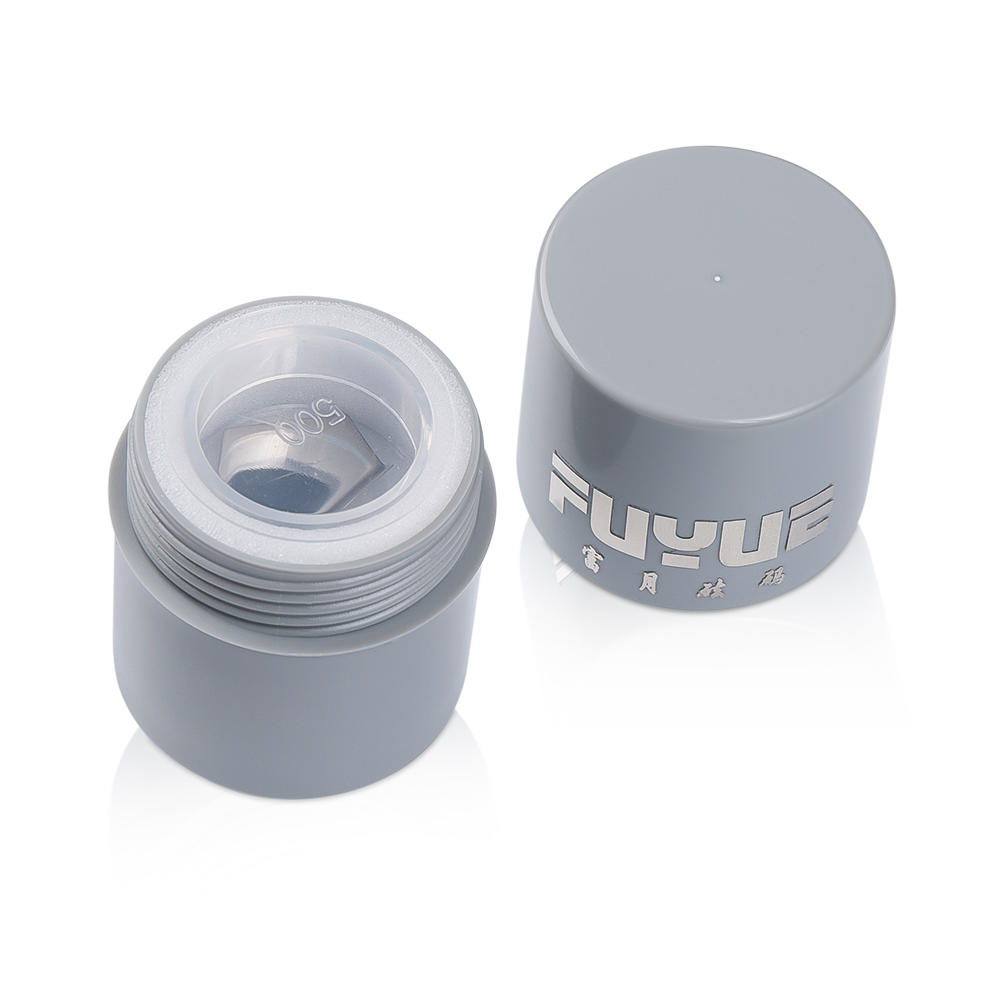

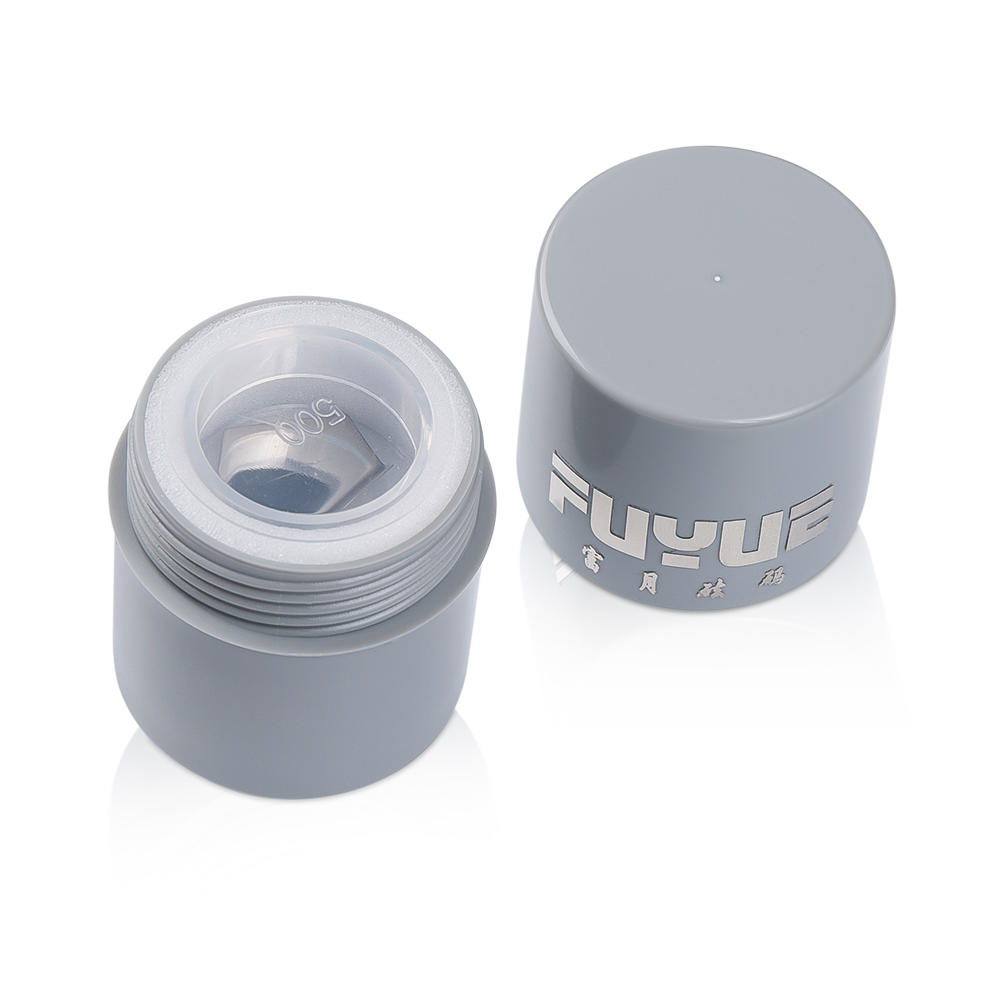

Material Selection:

Calibration weights are often made from materials with low CTE, such as stainless steel or specific alloys, to minimize the effects of temperature changes. The careful selection of materials with known thermal properties contributes to the temperature stability of the weights.

Metrological Considerations:

In precision metrology, temperature stability is crucial for ensuring that weights maintain their calibrated mass under different environmental conditions. Laboratories often control temperature and humidity to provide a stable environment for accurate measurements.

Accurate Calibration:

Calibration procedures typically involve measuring and adjusting weights at a specific temperature. If the calibration weights and the instruments used for calibration are not at the same temperature during calibration and use, there can be discrepancies in measurements. Temperature stability ensures that the weights remain accurate even when the environmental conditions change.

Laboratory Environment Control:

Laboratories that use calibration weights often have controlled environments to minimize temperature fluctuations. This control is essential for maintaining the stability of weights and ensuring the reliability of measurements.

International Standards Compliance:

Calibration weights are often manufactured and calibrated in accordance with international standards, which specify the temperature conditions under which calibration is performed. Compliance with these standards ensures that the weights remain stable and accurate across various laboratory environments.

Instrument Calibration:

Instruments used for weighing, such as balances and scales, are also affected by temperature changes. Calibration weights need to be compatible with the temperature range of the instruments to achieve accurate and traceable measurements.

Precision Applications:

In applications that demand high precision, such as pharmaceutical or scientific research, temperature stability becomes even more critical. Precise measurements are often required, and any variations in temperature can introduce errors in the results.

Minimizing Thermal Gradients:

Temperature stability helps minimize thermal gradients within a weight, ensuring that different parts of the weight experience similar temperature conditions. This reduces the risk of internal stresses or distortions that could affect accuracy.

Temperature stability is essential for maintaining the accuracy and reliability of laboratory calibration weights. It involves considerations of material properties, environmental control, and adherence to metrological standards to ensure that the weights perform consistently across various temperature conditions.

English

English