Industrial test weights are used for calibrating and testing weighing scales and systems. The function of a coating on these test weights serves several important purposes:

Corrosion Resistance: Many industrial environments can be harsh, with exposure to moisture, chemicals, and other corrosive agents. A coating on test weights helps protect the underlying material (often made of stainless steel) from corrosion, ensuring the weight's accuracy and longevity.

Accuracy Preservation: Coatings provide a smooth and consistent surface on the test weight, which is crucial for maintaining accuracy during calibration. Irregularities or imperfections on the weight's surface could affect its interaction with the weighing instrument, leading to inaccurate readings.

Cleanliness and Hygiene: In environments where cleanliness and hygiene are essential, such as pharmaceutical or food processing industries, coatings can facilitate easy cleaning and prevent contamination. A smooth, non-porous coating is easier to wipe down and sterilize compared to bare metal surfaces.

Reduced Wear and Tear: The coating can act as a protective layer against physical wear and tear. Over time, repeated handling of the weights and contact with surfaces could result in scratches and other damage that might affect accuracy.

Friction Reduction: Coatings can reduce friction between the test weights and the weighing instrument's surface. This helps ensure that the weight smoothly interacts with the instrument's mechanisms, preventing any resistance that could lead to measurement errors.

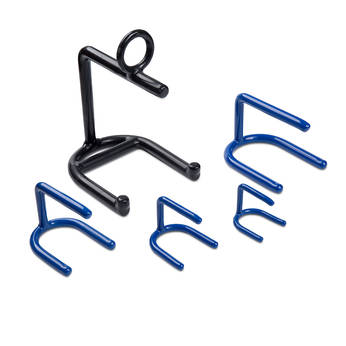

Identification and Differentiation: Coatings can be used to differentiate test weights by color or pattern. This is particularly useful when working with a variety of weights in a calibration or testing scenario, making it easy to quickly identify the appropriate weight.

Aesthetic and Safety Reasons: Coatings can also have aesthetic value, giving the test weights a professional appearance. Additionally, certain coatings might provide a non-slip surface, reducing the risk of accidents during handling.

Temperature Stability: Depending on the application, some coatings might contribute to temperature stability. They can help minimize the impact of temperature changes on the weight's accuracy.

Uniform Density: Coatings are carefully designed and applied to ensure that they don't significantly alter the weight's mass. This ensures that the weight maintains its intended accuracy during calibration.

Regulatory Compliance: Some industries have regulations or standards that require specific coatings to be used on test weights to meet certain criteria for accuracy and reliability.

In summary, the function of a coating on industrial test weights is to enhance their accuracy, durability, and suitability for a variety of testing and calibration environments, while also considering factors like cleanliness, safety, and compliance with industry standards.

English

English