In the manufacturing process, accurate weighing is the prerequisite for ensuring product quality. Whether it is the ratio of raw materials in the chemical industry, the preparation of finished products in the food industry, or even the formulation of drugs in the pharmaceutical industry, accurate weighing data is required to ensure product quality and stability. Any slight weighing error may lead to a decline in product quality, thereby affecting the company's reputation and market competitiveness.

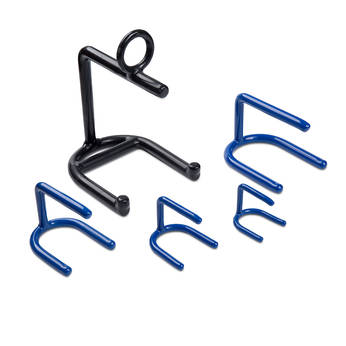

Scale calibration systems perform periodic calibration of weighing equipment using standard calibration objects. This work ensures the accuracy of the weighing equipment and provides calibration records and reports for tracking and review. The scale calibration system ensures that the weighing equipment is always in optimal working condition, providing a solid guarantee for the stability of product quality.

Scale calibration systems perform periodic calibration of scales by using standardized test objects, such as calibration blocks. This ensures the accuracy of the weighing equipment and provides a reliable data basis during the production process. Regular calibration can effectively detect and adjust the performance of weighing equipment to ensure that it is always in optimal working condition.

Regular calibration using scale calibration systems and equipment can effectively protect product quality. By ensuring the accuracy of weighing equipment, you can avoid weighing errors during the production process and ensure that the product's ingredient proportions and quality control meet standards. This helps reduce the failure rate in the production process, improves product quality and consistency, and enhances the competitiveness of enterprises.

Many industries are governed by strict regulations and standards, which include requirements for product weighing accuracy. Regular calibration of weighing equipment using scale calibration systems and equipment helps businesses comply with regulatory requirements and maintain compliance in their production processes. This helps avoid legal risks and financial losses that may arise from non-compliance.

Scale calibration systems and equipment play an irreplaceable and important role in ensuring product quality. By ensuring the accuracy of weighing equipment, scale calibration systems and equipment can help companies reduce the failure rate during the production process, improve product quality and consistency, while meeting regulatory requirements and enhancing the competitiveness of the company. Therefore, companies should attach great importance to scale calibration and perform regular calibration and maintenance to ensure stable and reliable product quality.

English

English